Maintenance and services

The competent and experienced team of FAMAK SA offers a full range of design, production, quality control, maintenance and modernisation services for handling, transport and crane machines and equipment.

The competent and experienced team of FAMAK SA offers a full range of design, production, quality control, maintenance and modernisation services for handling, transport and crane machines and equipment.

Many years of experience in designing, manufacturing and servicing the equipment, guarantees comprehensive, reliable and professional technical opinions regarding the equipment.

The opinions offer includes:

As a result of the inspections and measurements, the client receives:

CHAIN ROTATOR DOR 25t

Rotators are used to rotate large-size structures in the air, they are adapted to be suspended on cranes equipped with hook assemblies.

Technical parameters:

Q (DOR) = 25t

L chain = 15,5 m or acc. to individual needs

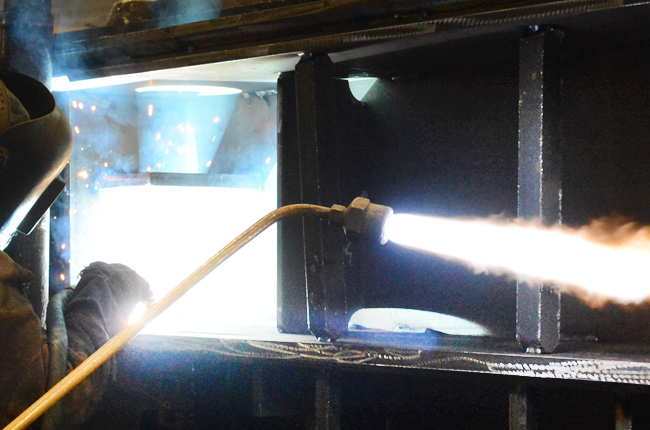

Manual shielded metal arc welding of:

Semi-automatic metal active gas welding of:

Automatic submerged arc welding of:

Semi-automatic flux-cored arc welding of S235, S355 steel.

Tungsten inert gas welding of:

Hardfacing using

Our welders are qualified in accordance with the PN EN ISO 9606-1 standard that allows technical equipment accepted by the Technical Supervision Office, Transport Technical Supervision or classification societies to be welded.We offer robotic welding for repetitive elements. The maximum values of elements welded by robots are: weight of up to 50 000 kg, length of up to 20 000 mm, width of up to 4 000 mm, height of up to 4 000 mm.

The FAMAK Group provides the following services:

Structures are shot blasted in special shot-blasting chambers by SCHLICK.

Thermochemical treatment is provided with the use of electric chamber furnaces (dimensions of the working chamber: /B x H x L 1.1 m x 0.7 m x 3.2 m), nitriding furnaces, carbonisation furnaces, universal feeders for induction hardening (gears module 5 to 37 – up to ø4,900 mm, rollers up to ø160 and L 1,900 mm) as well as sorbitisation services.

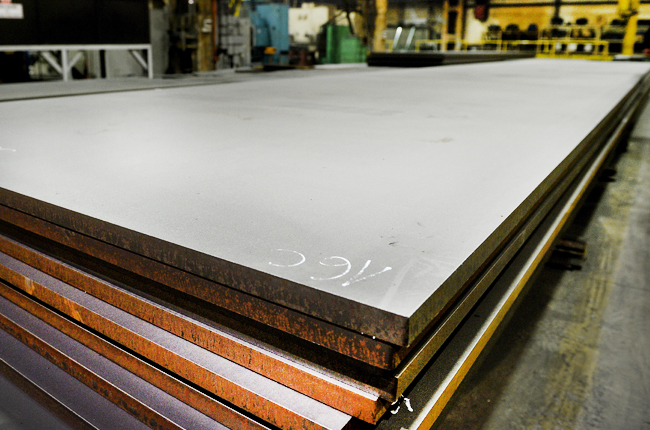

Before shot blasting the surface is cleaned using a semi-automatic process line, airless shot-blasting machine, and turbine shot-blasting machine. The maximum dimensions of sheets to be cleaned are 7000 mm x 6000 mm x 17,900 mm.

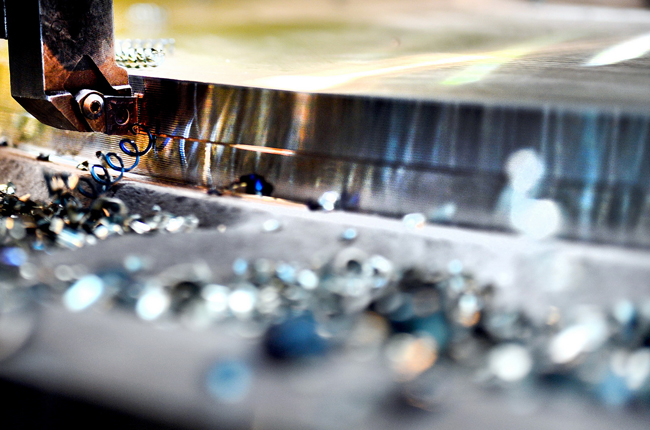

Machining is carried out with the use of heavy, medium and light claw lathes, numerically controlled lathes, carousel lathes, bench and plate drilling and milling machines, radial and jig drilling machines, vertical and tool milling machines, shaft, hole and planing grinders.

Steel structures are painted and dried in special painting and drying booths by ZUGIL.